How does PUR hot melt adhesive work?

Polyurethane Reactive (PUR) hot melt adhesives are a sophisticated class of adhesives widely used in various industries for their strong, durable bonds and versatility. Unlike traditional hot melts that solidify simply by cooling, PURs undergo a two-step curing process, which gives them superior performance characteristics.

The Two-Step Curing Process

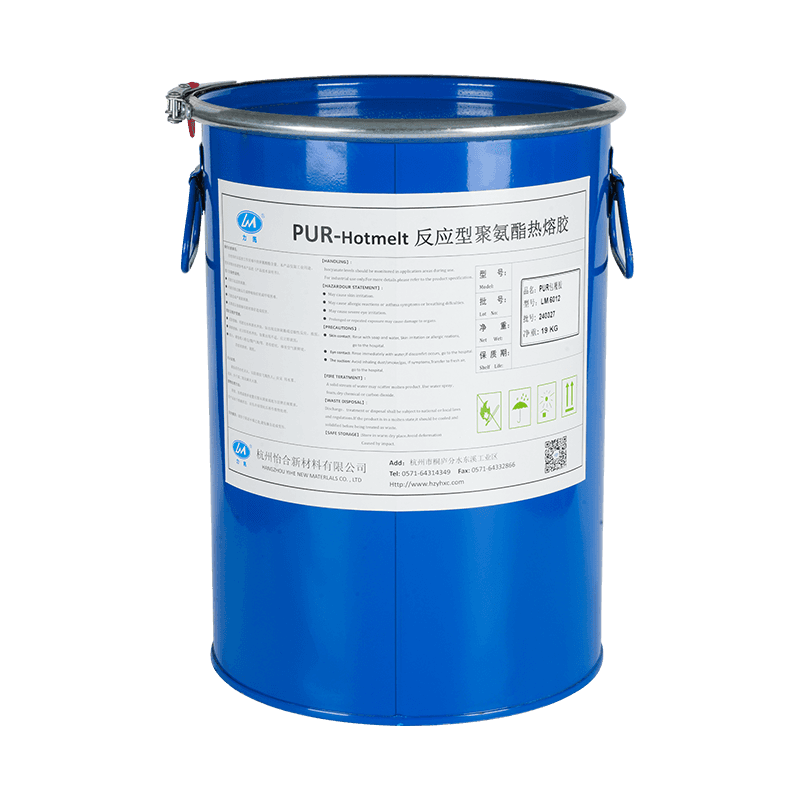

The "hot melt" aspect of PUR adhesives refers to their initial application. PURs are supplied in a solid or semi-solid state and heated to a specific temperature (typically between 100∘C and 140∘C) to become molten and flowable. This allows for easy application via standard hot melt equipment like nozzles or rollers.

Once applied to a substrate, the adhesive begins its first curing step: physical solidification. As the molten adhesive cools, it increases in viscosity and forms an initial bond, providing immediate handling strength. This rapid green strength is a key advantage, allowing for quick processing and assembly in manufacturing lines.

The second and more critical curing step is the chemical reaction. This is where the "reactive" part of PUR comes into play. PUR adhesives contain isocyanate functional groups that react with trace amounts of moisture present in the air or on the substrates themselves. This reaction, known as cross-linking, forms strong, irreversible urethane polymer chains.

This cross-linking process typically occurs over several hours to days, depending on factors like temperature, humidity, and the specific formulation of the adhesive. As the cross-linking progresses, the adhesive's bond strength, heat resistance, chemical resistance, and overall durability significantly increase. The resulting bond is thermoset, meaning it will not remelt upon subsequent heating, offering excellent long-term performance.

Key Components of PUR Adhesives

The performance of PUR hot melts stems from their carefully formulated composition, which typically includes:

-

Pre-polymers: These are the backbone of the adhesive, usually polyols reacted with an excess of isocyanates to create reactive end groups.

-

Isocyanates: The key reactive component that facilitates the cross-linking reaction with moisture.

-

Additives: Various additives are incorporated to tailor the adhesive's properties, such as tackifiers to improve initial grab, plasticizers for flexibility, antioxidants for stability, and fillers for cost reduction or property modification.

Advantages of PUR Hot Melt Adhesives

The unique curing mechanism of PURs offers several significant advantages over traditional hot melts and even some solvent-based adhesives:

-

Superior Bond Strength: The chemical cross-linking provides exceptionally strong and durable bonds, often exceeding the strength of the substrates themselves.

-

Excellent Heat and Chemical Resistance: Once fully cured, PUR bonds are highly resistant to elevated temperatures, moisture, and a wide range of chemicals, making them suitable for demanding applications.

-

Flexibility and Durability: Many PUR formulations offer excellent flexibility, making them ideal for applications subject to stress, vibration, or movement.

-

Versatility: PURs can bond to a wide variety of substrates, including wood, plastics (PVC, ABS, PET), metals, fabrics, and composites.

-

Environmental Benefits: Being 100% solids, PURs contain no volatile organic compounds (VOCs), making them a more environmentally friendly option compared to solvent-based adhesives.

Applications of PUR Hot Melt Adhesives

Due to their robust performance, PUR hot melts are utilized across numerous industries. Common applications include:

-

Woodworking and Furniture: Edgebanding, profile wrapping (often referred to as PUR Profile Wrapping Adhesive or Reactive Polyurethane Hot Melt for Lamination), and panel lamination.

-

Textiles and Footwear: Bonding various fabrics, leathers, and components.

-

Automotive: Interior trim, headliners, and component assembly.

-

Electronics: Potting and encapsulation.

-

Construction: Panel bonding, flooring, and insulation.

-

Packaging: Specialized and demanding packaging applications.

In particular, for applications like wrapping profiles with decorative films, PUR Wrapping Hot Melt Adhesive (also known as Moisture-Curing Polyurethane Reactive Adhesive or Reactive PUR Hot Melt for Wrapping) is highly valued for its ability to create strong, water-resistant bonds that resist delamination even in challenging environments.

In summary, PUR hot melt adhesives represent a significant advancement in adhesive technology. Their dual curing mechanism provides an unparalleled combination of initial handling strength and long-term performance, making them a preferred choice for applications demanding high bond strength, durability, and resistance to environmental factors.