Why Choose Polyurethane PUR Hot Melt Adhesives for Your Manufacturing Needs

When it comes to bonding materials, Polyurethane PUR hot melt adhesives stand out as an innovative and reliable choice. These adhesives, which offer unmatched versatility and strength, are increasingly becoming the go-to solution for industries such as packaging, automotive, electronics, and more. In this article, we will explore why Polyurethane PUR hot melt adhesives are a preferred bonding solution for modern manufacturing.

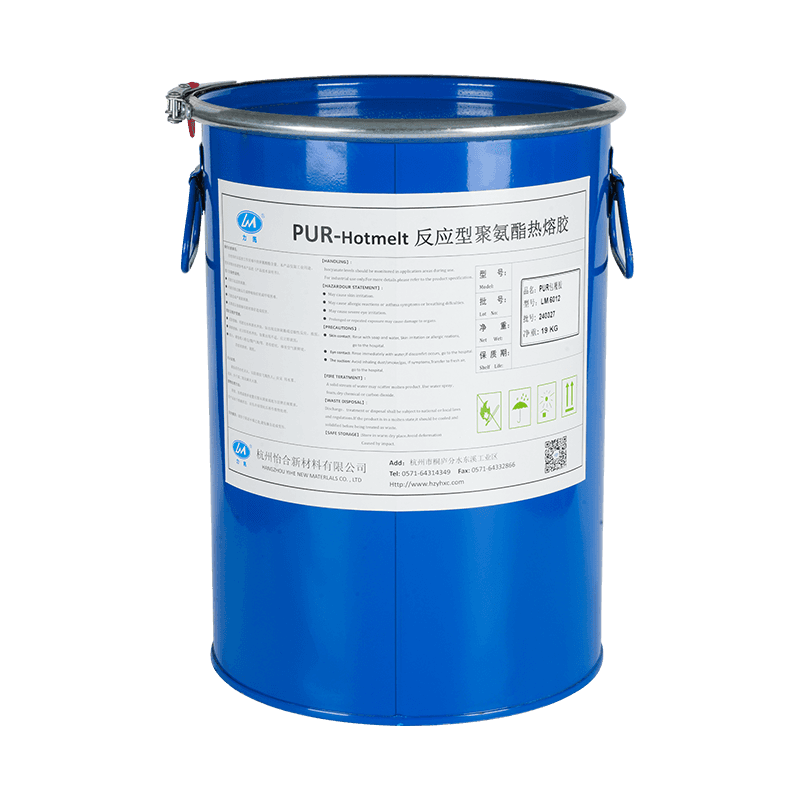

Understanding Polyurethane PUR Hot Melt Adhesives

Polyurethane PUR hot melt adhesives are thermoplastic adhesives that melt when heated and solidify when cooled, creating strong bonds between various surfaces. What sets Polyurethane PUR hot melt adhesives apart from other types of hot melts is their moisture-reactive property, which enhances the strength of the bond as they interact with the moisture in the air.

This unique characteristic ensures that these adhesives not only provide a fast and secure bond but also create long-lasting durability. They offer the perfect balance of flexibility and strength, making them suitable for applications that require both resilience and versatility.

Key Advantages of Polyurethane PUR Hot Melt Adhesives

The benefits of Polyurethane PUR hot melt adhesives are significant, and they play a crucial role in various manufacturing processes:

Superior Bonding Strength: Polyurethane PUR hot melt adhesives create durable and reliable bonds that withstand mechanical stress, temperature fluctuations, and exposure to moisture or chemicals. Their high adhesive strength makes them ideal for both light and heavy-duty applications.

Fast Processing and Application: These adhesives have a rapid setting time, which is essential in fast-paced manufacturing environments. The quick-drying nature of Polyurethane PUR hot melt adhesives helps reduce production time, allowing for efficient workflows and increased productivity.

Moisture and Temperature Resistance: These adhesives are highly resistant to environmental factors, such as humidity, extreme temperatures, and UV light. This makes them perfect for outdoor applications or areas where conditions may change frequently.

Eco-friendly and Safe: Polyurethane PUR hot melt adhesives are free of solvents, making them an eco-friendly choice. The absence of harmful chemicals also contributes to safer working environments for manufacturers, ensuring compliance with environmental standards.

Common Uses of Polyurethane PUR Hot Melt Adhesives

These adhesives are highly versatile, making them suitable for a broad range of applications:

Packaging: Polyurethane PUR hot melt adhesives are frequently used in packaging, where they ensure a strong and secure bond between cartons, boxes, and other packaging materials. Their fast setting time increases the efficiency of packaging lines.

Automotive Industry: In the automotive industry, these adhesives are used to bond components such as trims, weatherstripping, and interior panels. The strength and flexibility of Polyurethane PUR hot melt adhesives make them an essential part of the automotive manufacturing process.

Electronics Manufacturing: Polyurethane PUR hot melt adhesives provide effective bonding for electronic components, offering not only strength but also electrical insulation properties, ensuring product reliability and performance.

Furniture and Woodworking: These adhesives are used in the furniture industry for bonding wood, laminate, and other materials, providing a durable and flexible solution for both residential and commercial furniture.